Durable, versatile and high quality sustainable synthetic membranes for waterproofing roofs and coverings

RENOLIT has been setting trends for synthetic roofing membranes in Europe for over 45 years.

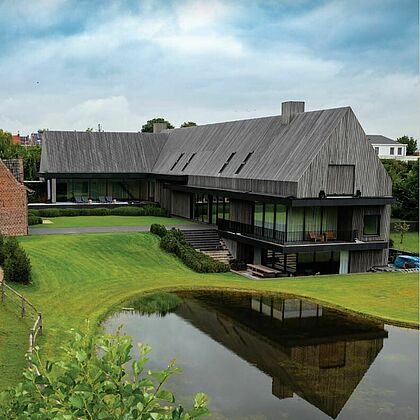

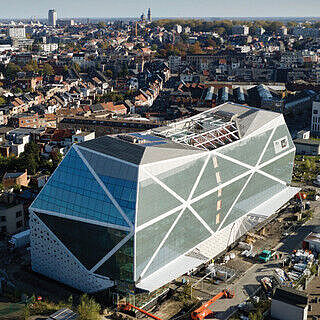

Our wide range of single ply roofing membranes and our innovative roof systems are used worldwide in new construction and renovation projects.

RENOLIT is a worldwide leader in the market of synthetic waterproofing membranes.

Our wide range of products and solutions meets the many demands and needs of architects, installers and facility managers.

Our solutions are innovative

In response to market demand, the classic roof systems have been supplemented in recent years by a number of innovative roof systems which provide reliable, durable and sustainable solutions.

Numerous customers all over the world have placed their confidence in RENOLIT products for the waterproofing of their roofs.

More RENOLIT products for roofing

Accessories

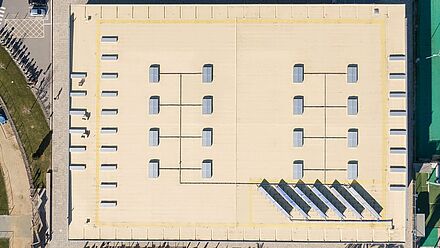

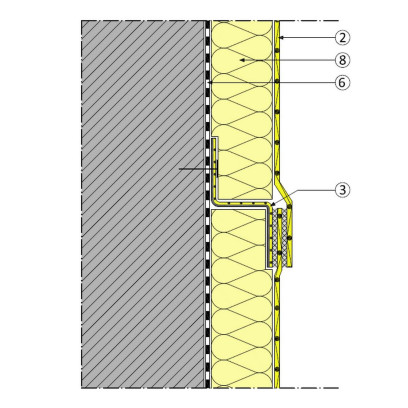

Application methods

The RENOLIT ALKORPLAN range consists of thermoplastic PVC-P roofing membranes. These have been used throughout the world for almost 45 years in the synthetic waterproofing of industrial flat roofs, for both new construction and renovation projects.

As standard, these roofing membranes are installed on the roof by mechanical fastening, bonding or ballasting.

Most beautiful realizations

Have a look at some videos of our most beautiful realizations.

YOU COULD ALSO BE INTERESTED IN

CONTACT US FOR MORE INFORMATION

RENOLIT Cramlington Limited

Phone: +44 1670.718283

Fax: +44 1670.590096

E-Mail: renolit.cramlington@renolit.com

Address: Station Road - NE23 8AQ Cramlington

Northumberland

RENOLIT Northern Ireland – Laydex Belfast

Phone: +44 2890.382.223

Fax: +44 2890.382.230

Address: 12A Falcon Road Adelaide Business Park

Belfast BT12 6RD - Northern Ireland - UK

RENOLIT Eire – Laydex Dublin

Phone: +353 1.642.6600

Fax: +353 1.642.6601

E-Mail: sales@laydex.ie

Address: Unit 3 - Allied Industrial Estate Kylemore Road

Dublin 10 - Ireland

RENOLIT BELGIUM Export Department

Phone: +32 55.33.97.11

E-Mail: sabina.ulens@renolit.com

Address: Industriepark De Bruwaan 43

9700 Oudenaarde - Belgium

RENOLIT Nordic A/S

Mr. Kenneth Witte (Technical Manager Scandinavia/Baltic)

Phone: +45 43 66 07 90

Mobile phone: +45 40 33 76 95

Fax: +45 43 64 46 38

E-Mail: kenneth.Witte@renolit.com

Address: Naverland 31 - DK-2600 Glostrup

Denmark

RENOLIT Magyarország Kft. / RENOLIT Hungary LLC

(Hungary, Romania, Serbia, Bulgaria, Croatia, Rep. Moldova, Kazakhstan, Kosovo)

Mr. Ferenc Szabo (Sales Manager)

Phone: +36 1.457.8164

Mobile phone: +36 20.355.0215

Fax: +36 1.457.8160

E-Mail: renolit.hungary@renolit.com

Address: Hegyalja út 7-13.

1016 Budapest - Hungary

DEK Czech Republic

Stavebniny DEK a.s.

Customer service

Phone: +420-510 000 100

E-Mail: stavebniny@dek.cz

Address: Tiskařská 10/257, Budova TTC

108 00 Praha 10 - Malešice

DEK Slovakian Republic

Stavebniny DEK s.r.o.

Phone: +421-2/32223022

E-Mail: stavebniny@dek.sk

Address: Kamenná ul. 6, 010 01 Žilina

RHEIN SYNTHETIC GROUP (Ukraine)

Phone: +38-0971049404

Mobile phone: +38-0445802238

E-Mail: info@rely.ua

Address: Pečerskij spusk, 13, int. 23 – Kiev