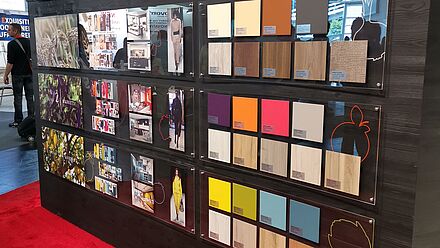

Design, made for you

Trends come and go, and it can be difficult to keep up with the pace of change in the world of commercial property and interior design in particular. At RENOLIT, we design modern, surface-enhancing films that are ahead of their time – with the aim of giving you greater design freedom. We strive to produce products that meet all your decorative and colour requirements and other specific needs.

Find more information here

PROCESSING OPTIONS

3D-THERMOFORMING

Thermoplastic 3D furniture films are high-quality surface materials for use with both membrane and membrane-free presses for the three-dimensional covering of wood composites (e.g. MDF), in the manufacture of furniture components and fronts and in interior design. These surface materials can be processed on all commercially available 3D presses by applying heat, pressure and vacuum in conjunction with a PUD adhesive to form a bond with the wooden composite.

STEEL LAMINATION

Steel sheet is coated on modified coil coating lines that were originally intended for the painting of steel panels. The substrate

can be steel, stainless steel or aluminium. Following the „finish first - fabricate later“ principle, the sheet is coated in the first processing stage, with the coated steel sheet then pressed or curved to form the end product.

FLAT LAMINATION

This processing method involves the continuous lamination of board materials on a roll laminating machine. Depending on the type of machine used, single or double-sided covering is possible using a wide variety of adhesives. Suitable substrates include MDF or chipboard, with metal and plastic also being ideal.

POST-FORMING

RENOLIT films can be processed on conventional post-forming lines. RENOLIT FILM is formed around the edge in two processing steps, similar to wrapping, and bonded by roller pressure and adhesive.

The continuous surface coating of surface and edge protects the substrate from moisture, amongst other things, and ensures a seamless appearance.

WRAPPING

This continuous process is suitable for the two-dimensional wrapping of profiles and panels used in furniture construction. The process is carried out on a wrapping machine with adhesive applied by roller, slot nozzle or doctor blade. MDF and chipboard are preferred substrates, however metal and plastic are also suitable.

FOLDING

Folding is a manufacturing process with its origins in the manufacture of loudspeakers and enables the formation of seamless edges - for example woodgrain designs can be wrapped around corners.

A panel laminated with RENOLIT 1D furniture film is used as the substrate, with a groove milled on its reverse side, so that it can be folded, for example to form a loudspeaker cabinet.

SELF ADHESIVE

Whether for a new item of furniture, a renovation project or for all types of damage repair, RENOLIT self-adhesive films are versatile and easy to use. Once a suitably matching film has been selected, the substrate is cleaned and dried. Then the repair film is cut to size and applied before final finishing is completed. RENOLIT`s Film Service also provides training courses for professional application.

THERMOLAMINATION

Films are bonded to a substrate under high temperatures and pressure. No adhesive is required in this process. It is important however that the substrate and the film have the same material base. For example, RENOLIT ALKORCELL (made of polypropylene) with RENOLIT WOOD-STOCK or with RENOLIT CORK-STOCK can be processed together to produce excellent results.

MATERIAL SELECTION

With a choice of PVC, PET and PP we offer our customers a variety of materials. Depending on the area of application and customer preferences, we can always find the right material to meet all requirements.