Market Unit Composites

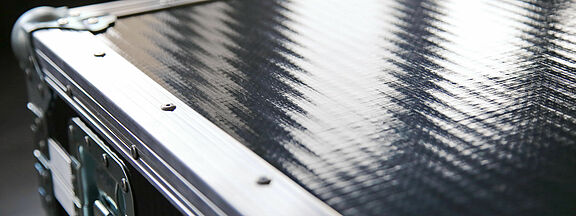

Composites is the competence center of RENOLIT for the production of thermoformable sheets and panels.

The Market Unit produces plastic composites in the form of rolls, sheets and honeycomb panels with divers polymeric, natural and mineral raw materials for the manufacture of, for example, automotive interior trim parts, building formworks and other customer-specific solutions where light weight, formability, mechanical performance and recyclability are key parameters.

Furthermore our products are used for applications in the construction industries as well as other industrial areas.

Recyclability

Our products are 100% recyclable.

We offer our customers the possibility of taking back discarded thermoformed

trim, which result from the processing of our products. This scrap material can

be granulated and re-introduced into the extrusion process.

Extrusion -> Thermoforming -> Recycling

The scrap milling can be implemented close to the thermoforming process line. We are available to cooperate to install a milling machine close to the line to make the regrind material to be collected in big bags and shipped to our company.

Process optimization

Thanks to our more than forty years experience, RENOLIT engineers define the right process parameters together with the customer minimizing scrap and increasing the efficiency of the production. Upon request, all the optimization actions can be performed at the customer manufacturing site.

Mold supplier support

Composites cooperates with the best mold suppliers to reach the right mold definition. For the tooling design and manufacturing for our classic WPC sheet RENOLIT WOOD-STOCK we worked with all the main mold suppliers in the sector.

Mold testing area

In our plant in Buriasco (Italy) we have the possibility to define the mold and/or test a prototype using a manual production line with an infrared oven and a press. By the use of a prototype tool made out of wood, we can offer a very fast and economical production of prototypes.

Further processing support

We work with other industry specialists to develop a total package for you.

Thermoforming Advantages

One-step process

High formability

Can join different covering materials

Glue free

Different type of cutting

Can obtain very deep drawn shapes

Dimensional stability of the finished part

Inserts made of various materials

Fast Cycle

Simple tooling

100% recyable

The Locations of Composites

Automotive

Lightness and recyclability combined with outstanding technical

characteristics make our Polypropylene composites the material of

choice in the automotive industry.

Applications

Building

Our sheets have been designed to obtain the best performance in the building industry.

We developed a special sheet for formworks applications. Even though we offer a

wide range of sheets for diverse building applications.

Applications

Panels

With its outstanding properties our versatile RENOLIT GORCELL panels impress in every area.

Applications

Our Contact Persons for you

Ulisse D'Eramo

General Manager SMU Composites

| Fax: | +39.0121.56323 |

| Mobile: | +39.327.6318406 |

| Email: | Ulisse.Deramo@renolit.com |

| Address: |

Via Pinerolo 7, 10060 Buriasco (TO) Italy |

Rahul Chivate

(Managing Director APPL GOR India)

| Email: | rahul.chivate@applgorindia.com |

| Address: |

APPL GOR India 680/2 Pune-Nagar Road |

Regine Koudela

Head of Sales & Marketing Mobility

| Fax: | +39.0121.56323 |

| Mobile: | +39.345.5889578 |

| Email: | regine.koudela@renolit.com |

| Address: |

Via Pinerolo 7, 10060 Buriasco (TO) Italy |

Alfredo Sellitti

Head of Sales & Marketing Formwork

| Phone: | +39.0121.569554 |

| Fax: | +39.0121.56323 |

| Mobile: | +39.345.0598339 |

| Email: | alfredo.sellitti@renolit.com |

| Address: |

Via Pinerolo 7, 10060 Buriasco (TO) Italy |

Raffaella Giovannini

Head of Sales & Marketing Non Automotive

| Phone: | +39.0121.569529 |

| Fax: | +39.0121.56323 |

| Mobile: | +39.324.6624773 |

| Email: | raffaella.giovannini@renolit.com |

| Address: |

Via Pinerolo 7, 10060 Buriasco (TO) Italy |

Jim Lyon

Technical Sales Manager Composites NAFTA

| Phone: | +001.563.580.4979 |

| Email: | james.lyon@renolit.com |

| Address: |

RENOLIT Gor S.p.A. 2935 S Fish Hatchey Road #355 Madison, WI 53711 |